Linen Damask

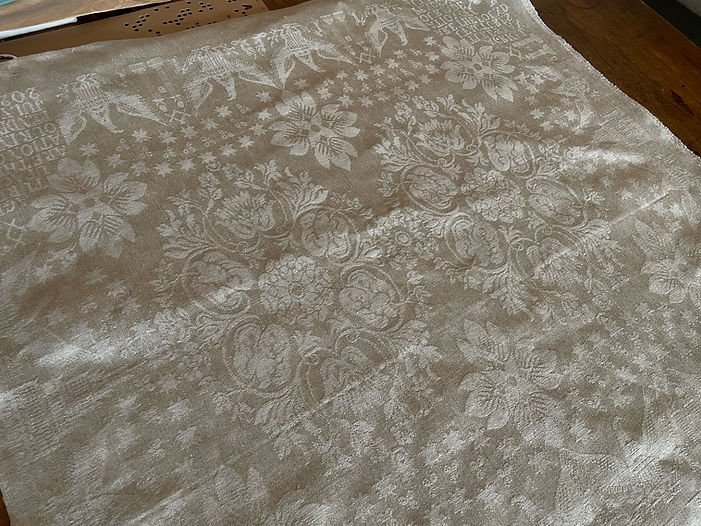

From my first encounters with figured linen damask I have been captivated by this textile's intense beauty. Constantly changing with the light, the patterning on damask has an almost magical ability to come and go, revealing fleeting glimpses until the viewer catches the cloth at just the right angle. Woven out of fine singles linen yarn, the eight-leaf satin weave structure is dense and strong enough to last through decades of use as proven by numerous surviving examples as old as the 16th century.

The patterning in damask comes from the contrast of areas predominated by warp yarns and areas predominated by weft yarns. As the opposing directions catch the light differently, they appear lighter or darker than each other, displaying the pattern created by the interlacement of the yarns alone. Viewed directly with flat lighting, the pattern recedes and disappears. Angle the damask or the light, and suddenly the design erupts with life. This effect is heightened by the use of singles linen yarns and mangling to press the fibers and bring out their natural high gloss. Damask is a truly interactive textile, best enjoyed by handling and movement.

In 2019 I acquired a Jacquard machine from the 1850s–1860s built in Ireland or Scotland for the linen damask industry. This Jacquard had been harnessed for weaving coverlets by its previous owner, but in early 2023, after several years of research, I converted the harness back to damask weaving. Working looms in Ireland and Scotland provided important information, as did books like T.F. Bell's Jacquard Weaving and Designing, published in 1895.

The process began by determining the layout of the harness. Following 19th-century practice, the harness is divided in thirds. One half of the hooks control a straight section in the middle of the harness to allow for single direction patterning, while the other half of the hooks create a cross border which mirrors on either side.

Image from Fred Bradbury, Jacquard Mechanism and Harness Mounting.

After the arrangement was determined, a comber board could be made by drilling carefully spaced holes into a thin piece of beech and the harness cords could be measured and entered into the board.

810 brass mails and steel lingoes were specially made and suspended from varnished linen twine. After the harness was attached to the Jacquard, the cords were tied to the mails and the mails adjusted to level the harness.

With the harness leveled and additional treadles, lamms, and a back beam added to the loom, the loom could now be warped with 3,240 ends of singles linen. Four warp ends are entered into each of the 810 mails, the lease of the warp recreated in front of the harness, and then each end is drawn into the eight-leaf satin pressure harness heddles. Having twenty-five mails for every inch of the comberboard, the damask cloth contains 100 warp ends and roughly the same number of weft picks in every inch. With fewer than twenty of these particular linen damask Jacquard machines left in existence, it's an incredible thrill to see this one working as well today as it did 170 years ago. Linen damask may be ordered through my shop, or contact me to discuss the creation of a custom design.